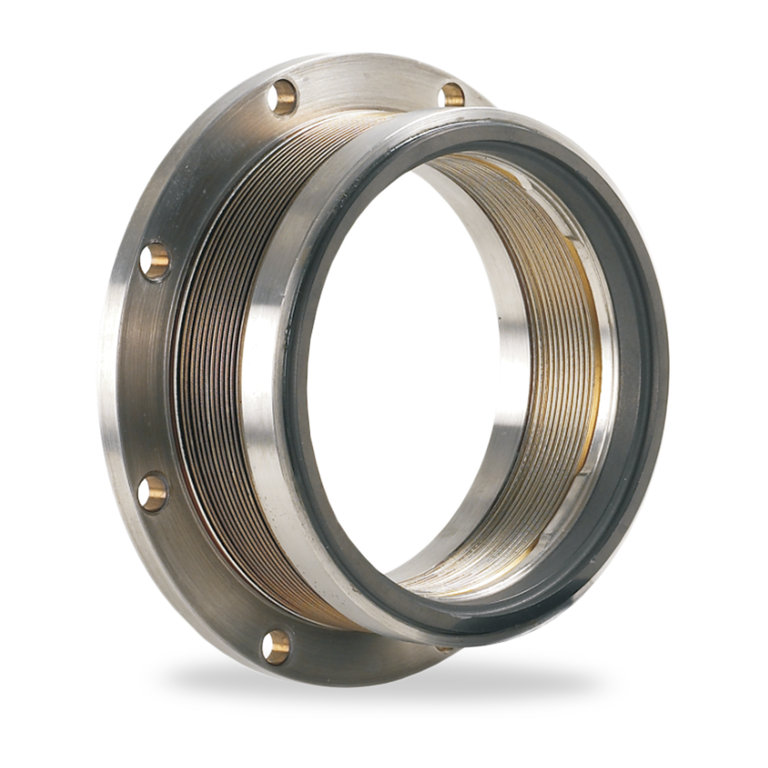

High temperature seals

Y16, Y19, Y66, Y99

High temperature seals

Y16, Y19, Y66, Y99

High temperature seals

Y16, Y19, Y66, Y99

Features

- Rotating bellows seal

- Balanced

- No dynamic O-Ring, no hang-up, no shaft sleeve damage

- Uniform seal face loading

- Independent of direction of rotation

- Ideally suited for highly corrosive and abrasive media

- Compact design

Advantages

- Over 35 years of running reference in the field

- Resistant to abrasive particles

- Self cleaning, non-clogging design

- Long seal life due to vibration dampeners at bellows

- Ideal seal for very low as well high temperatures

Materials

Seal ring: Carbon graphite, Silicon carbide, Tungsten carbide

Mating ring: Silicon carbide, Tungsten carbide

Bellows: AM 350

Metal parts: SS 316, other materials on request.

Mating ring: Silicon carbide, Tungsten carbide

Bellows: AM 350

Metal parts: SS 316, other materials on request.

Recommended applications

- Process industry

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Power plant technology

- Water and waste water technology

- Building services industry

- Food and beverage industry

- Sugar industry

- Horizontal and vertical pumps, agitators, mixers

Recommended piping plans

API Plans 01, 02, 03, 11, 12, 13, 14, 21, 22, 23, 31, 32, 41, 52, 53A, 53B, 53C, 54, 55, 61, 62, 65A, 65B, 66

Similar products

Dry running emission containment seal Y11

- Stationary bellows seal

- Uniform seal face loading

- Independent of direction of rotation

- Special carbon grade for dry running capability

- Seal with low face pressure hence less seal face heat generation

- Compact design

- Mating ring with wave spring design

- Vibration dampener for bellows

- Outboard emission containment seal used along with inboard pusher or bellows seal

High temperature advanced seals YE400, Y014

- Stationary bellows seal

- Balanced

- Uniform seal face loading

- Independent of direction of rotation

High temperature stationary seals Y14, Y44

- Stationary bellows seal

- Balanced

- Uniform seal face loading

- Independent of direction of rotation

- Self-cleaning bellows design