Process water extraction in milk powder production

At Vreughdenhil Dairy Foods, one of the world's largest manufacturers of milk powder, process water is pumped by 13 Homa type CMX24/34 pumps at the Gorinchem, Netherlands location. The pump cases are made of stainless steel.

The correct seals in this case are EagleBurgmann MG1 in tandem arrangement. Temperature: t = 40 °C (104 °F), pressure: p … 3 bar (44 PSI), rotational speed: n = 960 min–1 or 1,450 min-1.

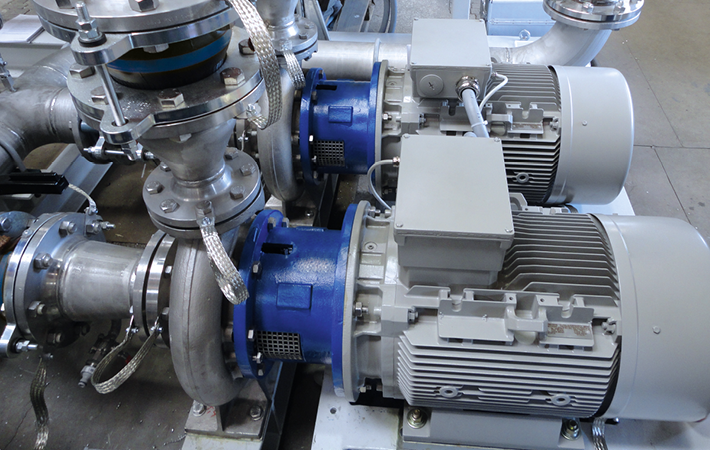

EagleBurgmann M7N in ultrapure water plant

The pumps in an ultrapure water plant in Germany are sealed with EagleBurgmann M7N component seals. The medium is pumped with a temperature of 30 °C (86 °F). It has a conductivity of ≤1 μS/cm. An effective equipotential bonding must be ensured in order to prevent the resulting problem of electrochemical corrosion at the sliding faces of the seal. The entire system is correspondingly grounded for that reason.

Metal bellows seals for sustainable heating of greenhouse systems

The Dutch company Duijvestin is growing tomatoes in Pijnacker, one of Europe's largest greenhouse systems in Europe. The heating of the 13.5 hectare complex was converted to geothermal heat in 2010. Pumps of the SPX Johnson CombiLine series ensure the hot water is lifted up from the 2,000 meter depths. The pumps are sealed with EagleBurgmann Mtex-DE metal bellows seals in double version. They are supplied by an EagleBurgmann TS1016 system in accordance with API Plan 53A.

Operating conditions: Temperature: t = +70 °C ... +75 °C (+158 °F … +167 °F), pressure: p = 4.5 barg (65.3 PSIG), rotational speed: n = 2,950 min-1.

EagleBurgmann HRC1 with DiamondFace for the production of electronic components

Two KSB pumps are installed at ST Microelectronics in France to pump ultrapure process water (σ = 0.05 μS/cm) for the manufacture of electronic components. After retrofitting the shaft seal to an EagleBurgmann HRC1 with DiamondFace coating of the seal faces, operating periods were extended by a factor of 250.

Operating conditions: Temperature: t = +20 °C (68 °F), pressure: p … 2 bar (29 PSI), rotational speed: n = 3,000 min-1, sliding velocity: vg = 10 m/s (33 ft/s).

EagleBurgmann Splitex in pumps for seawater conveying

LUK Oil operates the ISAB refinery to the north of the Italian city of Syracuse on Sicily's west coast and has retrofitted its Flowserve 20LNH multistage pumps with respectively two EagleBurgmann Splitex split mechanical seals. The pumps convey seawater in cooling towers.

Temperature: t = +32 °C … +40 °C (+90 °F … +104 °F), pressure: p … 4 bar (58 PSI), rotational speed: n = 980 min-1. The 6-inch seals are operated with API Plan 02.

Cartex cartridge seals handle difficult media

SPX-Johnson type CFB 200-400 pumps for the recirculation of separated water are installed in a membrane ultrafiltration plant of the Dutch Water Treatment Company. The medium is very aggressive, has a solids content of 50 mg/l and exhibits dissolved solids of up to 3,800 mg/l. The mix also includes toxic hydrogen sulphide (H2S) which requires reliable leakage detection. The pumps are sealed with EagleBurgmann Cartex-DN double seals. The seals are supplied by means of the EagleBurgmann TS1016 system as per API Plan 53.

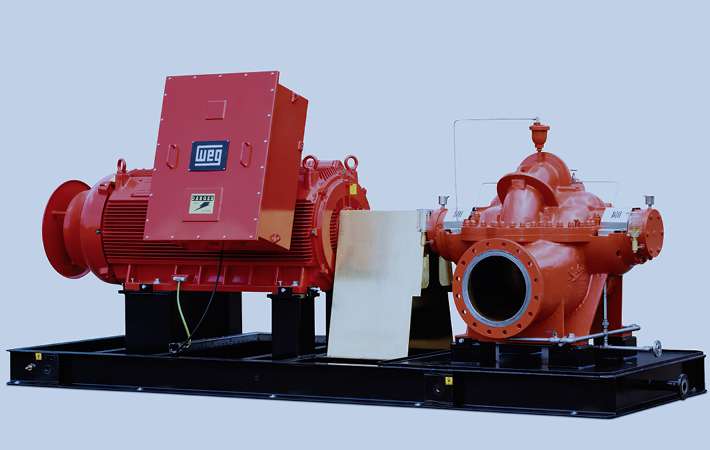

Cartex mechanical seals for fire water pumps skids on oil field

Nijhuis HGT1-350.500 fire water pump skids are deployed in the Tempa Rossa oil field in Italy, which is operated by Total E&P Italia. The water is provided as required with a volume of 1,330 m³/h and a pressure of 8.4 bar (122 PSI). The horizontally split pumps with bearings on both sides are usually sealed with EagleBurgmann Buraflon compression packings, but Cartex-SN cartridge seals were installed in this case.

Multistage sterile pumps for the distribution and storage of pharmaceutical waters

Multistage Hilge sterile pumps of the Contra series are also installed for the distribution and storage of various qualities of pharmaceutical waters. They are CIP and SIP capable and EHEDG certified; parts with product contact are executed in the Hygienic Design. Successfully sealed with EagleBurgmann type SHJ mechanical seals.

Typical operating conditions: Temperature: t = +20 °C … +90 °C (+68 °F … +194 °F), pressure: p = 2 … 9 bar (29 … 131 PSI), steam sterilization at +121 °C … +135 °C (+250 °F … +275 °F).

Elastomer bellows seals successfully seal wastewater block pumps

The UNIPUMP wastewater block pumps of the German manufacturer Herborner Pumpentechnik are preferably installed in process engineering plants, e.g. for the safe function of wastewater transport systems on ships. The pumps are sealed with an EagleBurgmann MG1 single elastomer bellows seal made of non-wearing materials. Optionally available in double version with quench for dry running prevention.

Operating conditions: Temperature: t … 60 °C (140 °F), pressure: p … 6 bar (87 PSI), rotational speed: n … 3,600 min-1.